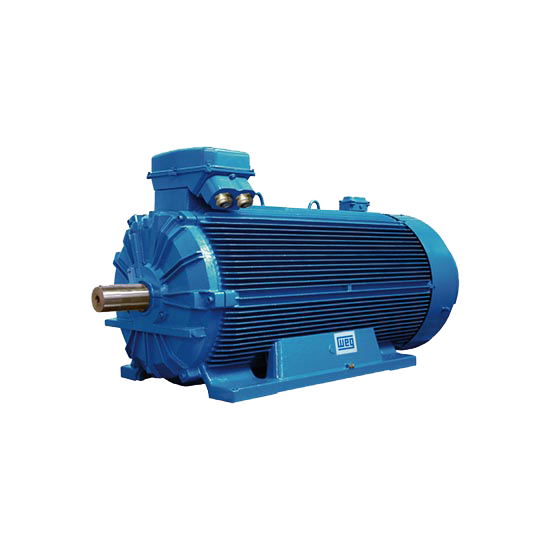

BFN Line - Low Voltage (ATEX)

BFN Line - Low Voltage (ATEX)

( Up to 1,120 KW )

Application:

Environment where an explosive atmosphere will probably not be present under normal operating conditions and, if any, this will be for short period of time, that is, an explosive atmosphere may be present accidentally.

The environments are classified as Zone 2, groups IIA, IIB and IIC, and as Zone 22, groups IIA, IIB and IIC. The most common gases included in this classification are: acetone, ammonia, benzene, butane, butanol, buthylic alcohol, ethane, ethanol, acetate of ethyl, gasoline, heptanes, hexanes, natural gas, methanol, oil naphtha, propane, propanol, toluene, esthyrene, solvents in general, acetaldehyde, cyclopropane, diethylic ether, ethane, monoxide of carbon, acetylene, butadiene, oxide of ethane, hydrogen, oxide of propylene and gases containing over 30% of hydrogen.

Standard Features:

Output: 0.12 up to 250kW

Multivoltage (220-240/380-415//440-460V or 380-415/660-690//440-460V)

Self Ventilated (TEFC)

EFF1 Premium Efficiency

Cast iron frame 63 up to 355M/L

Mounting: B3T

Degree of Protection: IP55

Squirrel cage rotor/Aluminium die cast

Zone 2: class of temperature T3

Zone 22: maximum external surface temperature T 125°C (dust layers up to 5mm)

Stainless steel nameplate AISI 316

Class F insulation with T 80K

Continuous duty - S1

Ambient temperature: 40°C , 1000 m.a.s.l.

Regreasing nipples from frame 160 and above

Thermistors 155ºC - 1 per phase

Thermistors 140° C - 1 per phase

Note: If the motor is used at Zone 2 (gas), 155°C PTC is required as it complies with the worse condition for such application. The 140°C PTC may be used as alarm. In case motor is used in areas classified as Zone 22(non-conductive dust), 140°C PTC must be applied, so as to ensure the worse condition is also met under such application.

Metric thread cable entries in terminal box

Earth lug inside the terminal box

Suitable for Inverter Duty applications*

Epoxy based paint plan: RAL 5010

*For additional details about Inverter operation, please contact our technical support.

Optional Features:

Single voltage (other voltages)

Degree of Protection: IP56, IP65 or IP66

Other mounting configurations

Thermal protection:

Thermostats

RTD-PT 100

BFN Line - Low Voltage (ATEX)

( Up to 1,120 KW )

Description:

The present catalogue refers to TEFC, Low Voltage, three phase, squirrel cage induction motors, ribbed frames, BFN series, with shaft height from 315 to 500 mm, with following powers:

kW RPM

160 up to 710 kW

3000 RPM

160 up to 1120 kW

1500 RPM

110 up to 900 kW

1000 RPM

90 up to 800 kW

750RPM

Even for outputs above 90kW, this range of motors has high efficiency design and is in line with the same levels of efficiency classification EFF2 as established between CEMEP and European Community.

Particular specifications related to Hazardous Areas :

The motor series BFN have the specification code EEx nA, and comply with European Standards EN 50014 and 50021, for the gases group II and Temperature Class T3.

This motor series has the CE ( ) marking in compliance with European Directive 94/4/EC (ATEX), and are classified as equipment group II (Surface Industries), category 3, suitable to use on Zones 2. Gases and Vapours (G).

The Non Sparking motors in this catalogue are self certified, according to the above standards, or under request to be certified by the Notified Body Baseefa in UK, accredited organization by EU.

Standards:

Motor series BFN are manufactured according to IEC and equivalent national standards:

Rating and performance - IEC 60034-1

Outputs and dimensions - IEC 72 and EN 50347

Mechanical protection - IEC 60034-5

Cooling method - IEC 60034-6

Mounting arrangements - IEC 60034-7

Insulation - IEC 85

Terminals identification and direction of rotation - IEC 60034-8

Noise limits - IEC 60034-9

Vibration limits - IEC 60034-14

Construction:

Mechanical protection: IP55

Insulation: Class F

Temperature rise: 80 K

Frames: are in cast iron

Terminal boxes:

For frame sizes 315L and above, the terminal boxes are separated from the motor frame and are in cast iron with a pressed steel cover.

As standard, the terminal boxes are supplied with cable entry in the right hand side viewed from the drive end, however, this may rotated by 180º to permit cable entry on the left hand side.

As option, special terminal box arrangement and sizes are available in fabricated steel

Endshields/flanges: are in cast iron.

Fans:

For frames 315L and above, the fans are made from polypropylene, aluminium alloy or fabricated steel, depending on the frame sizes and the speeds.

Fan covers: are in pressed or fabricated steel.

Finish: Industrial paint system, standard color RAL 5007.

Voltage and Frequency:

Frame size 315L:

As standard, these motors are wound to operate on either 50 Hz or 60 Hz, over the following voltage ranges:

380-415 V - 50HZ / 440-480 V - 60 Hz

A tolerance of -5% up to +6% is permitted for any value of rated voltage within these intervals.

The electrical data described in the present catalogue, is based on the standard supply voltage 400V.

Depending on actual supply voltages/frequencies, this data may vary slightly but the variations will generally remain within the tolerances given in IEC 60034-1.

FFrame sizes 355 and above:

These motors are spot wound for any voltage within the following range:

380 V <= U <= 690 V 50 Hz for powers up to and including 630 kW

500 V <= U <= 690 V 50 Hz for powers above 630 kW